GPH Quantum Re-bar is completely inclusion free because it contains:

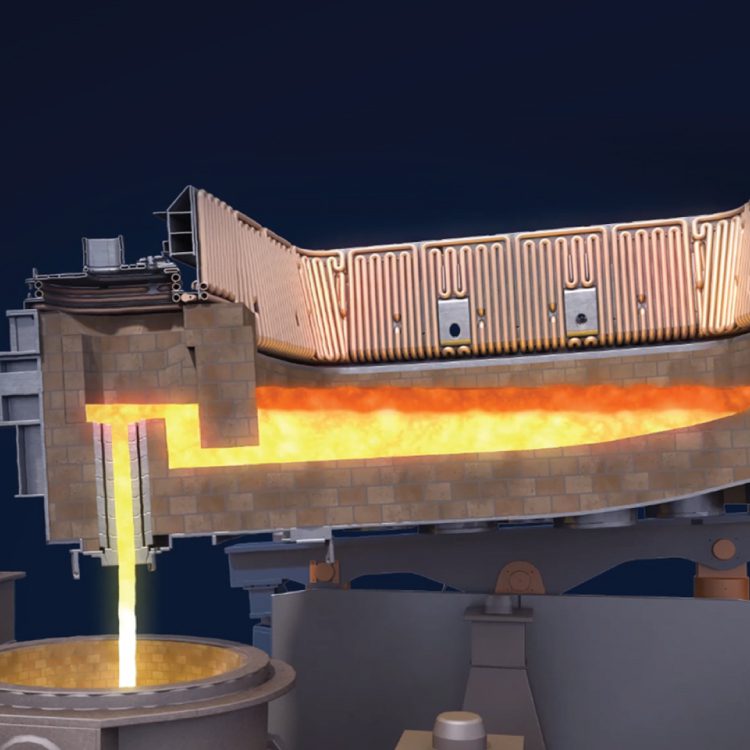

- Scrap pre-heating process: The GPH QUANTUM pre-heating chamber of the arc furnace heats the scrap to a temperature of 600-degree C. During this process, it removes the paint, rust, moisture and primary impurities present in the scrap.

- Oxygen lancing and argon bottom purging: GPH QUANTUM removes unnecessary carbon and phosphorus by oxygen lancing and bottom purging in the arc furnace, turning the melted mixture into a homogenized mixture.

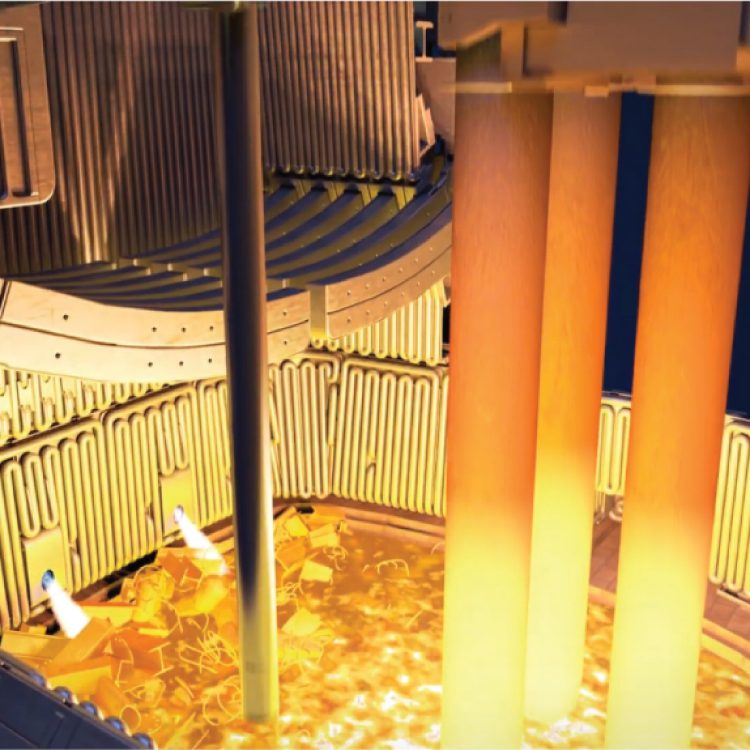

- Flat bath operation and bottom tapping: PURE FLAT BATH OPERATION is done by preparing 70 MT HOT HEEL in GPH QUANTUM arc furnace having holding capacity of 150 MT, where the chemical reaction of carbon and oxygen creates FOAMY SLAG. and removes phosphorus and other impurities. 80 MT 100% slag free metal is collected into the ladle by tilting the furnace at a 4-degree angle through bottom tapping in a siphonic process.

The GPH QUANTUM Re-bar is much more earthquake resistant than other Re-bars in the market for its 100% refined. So the engineers rely on GPH QUANTUM Re-bar for any mega structure.