TECHNICAL SUPPORT

- Rebar Detailing Services -Estimating, Scheduling and Project Management

- Design & Engineering services (architecture and structural design)

- Logistics Management, On-site Delivery and Bundling

QUALITY TESTS

Spectrometer

GPH Ispat Limited has the latest version of Spectrometer from Spectro lab, Germany. It has the facility to test chemical composition of mild steel, stainless steel, cast iron, tool steel and high manganese steel.

With this machine, 25 elements of steel can be checked by a single spark within a moment. We use Reference Samples (CRM) for efficient calibration purpose.

ED XRF

With the help of ED XRF (Energy Dispersive X-ray Fluorescence Machine) the testing of incoming raw material will be done in a very precise and efficient way.

Also process analysis and process developmental activity will be done using this ED XRF. This machine is much expensive & unique one in our plant that many steel plants of Bangladesh unable to afford.

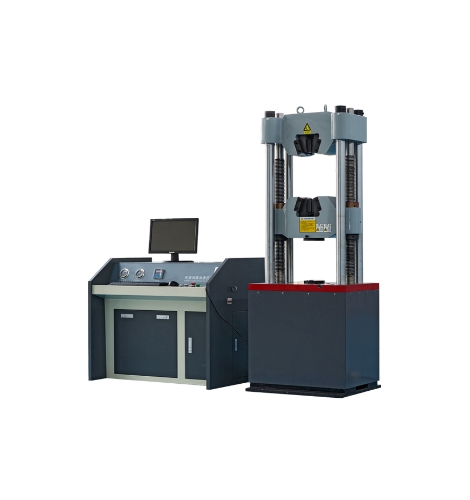

Universal Testing Machine

For extensive quality control GPH ispat has Universal Testing Machine of 2000 KN capacity to check the yield strength, tensile strength, tensile/yield ratio, elongation at maximum Force (EMF), elongation after fracture (every 15 minutes interval) of rebar up to 8-50 mm diameter.

This machine is calibrated by BRTC BUET to have precise test result.

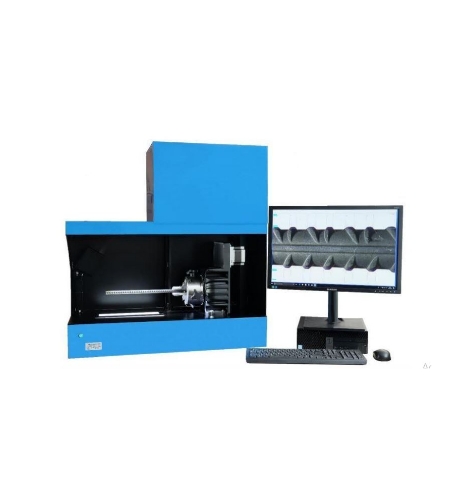

Profilometer

By using this sophisticated Profilometer, we can automatically measure the Rebar transverse rib height, Longitudinal rib height, Transverse rib spacing, Longitudinal rib width, Rib Inclination, Flank Inclination, Projected Rib Area, Relative rib area etc.

This will ensure rib geometry as specified in standard which gives guarantee for proper bonding with concrete & fatigue resistance.

Bend Testing Machine

Every 30 minutes interval we perform Bend and every 90 minutes interval Re-bend test for checking Bend property and Aging property. It confirms how much ductile the material is.

Universal Hardness Tester

This Universal Hardness Tester is bench type and fully automatic equipped with Brinell, Rockwell and Vickers hardness testing facility.

Research and development department use it to check for product versatility and product development.

Metallurgical Microscope

GPH has Inverted metallurgical microscope with CCD camera attachment with image analysis software. By this device, the impurity content, micro-structure, grain size, decarburization will be checked.

By ensuring impurity free steel GPH will give excellent quality steel through the country.

Macrostructure Etching setup

This is used for etching of billet slice for macro analysis of transverse and longitudinal section. The macro analysis of billet will be done to check the crack, blow hole, center segregation, center piping, equi-axed zone etc.

By ensuring internal defect free billet, good quality rebar will be produced.

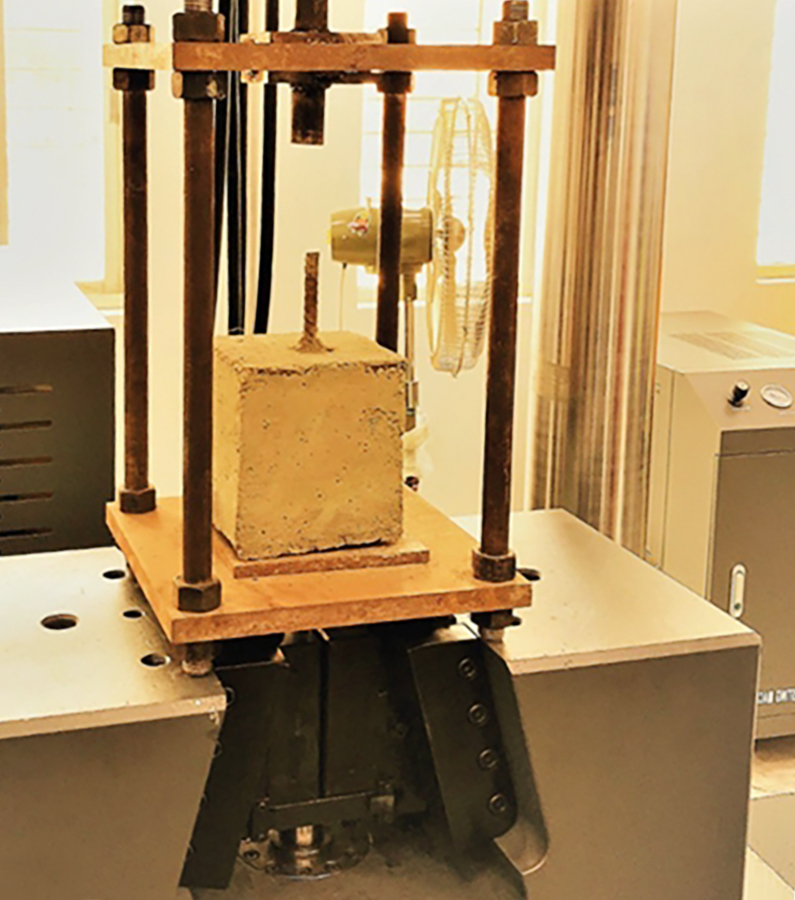

Bond Testing Machine

Bonding between rebar and reinforcement concrete is very much important in construction. In RCC, the rebar takes cares of tension load where the rest part takes care of compressive load. If the bond between rebar and concrete-cement matrix is not good, the RCC structure will fail.

The bond test machine is used for comparison of the bonding strength of different types of reinforcing bars with concrete by means of a pull-out test.

Charpy Impact Test

Although an RCC or steel structure is made considering design strength of steel structure, it can collapse due to sudden impact load during earthquake.

So, it is important to test the impact resistance through impact test. GPH has that facility for impact testing of steel